Major Refit of La Vita - Part 1

Wednesday, September 22, 2021

Every decade or so, a cruising boat needs some serious spa time. If a lot of work is done, it is called a refit. Late in 2020, we decided that for us to comfortably go further afield, we needed to replace the almost 40 year old Isomat mast with a new Selden furling mast. For you non-sailors, this means the main sail furls inside the mast instead of falling all over the deck when lowered and everything can be done from the safety of the cockpit. We also planned several other upgrades to make it possible for us to continue to cruise as we age. In hindsight, we were naive on both how long this refit would take and how much it would cost. Some of the delay was due to our time and energy being diverted to unexpected side projects, commonly called “scope creep.” And some of the delay was on the service side -- marine service providers are swamped with work and often so backed up they are not accepting new customers. It turns out that when people can’t travel, they work on their boats. And a lot of our problems were caused by an inability to obtain parts quickly due to the COVID-19 supply chain disruption. But enough about the problems of the last few months. We have learned a lot, both good and bad, about how to keep moving forward under difficult conditions and we have made much progress.

After spending a cold, wet and windy winter in North Carolina at the Morehead City Yacht Basin, we arrived at Cobb’s Marina in Norfolk on March 31, 2021, right on schedule. After all, we were expecting our new Selden mast to arrive at Cobb’s the first week in April. We had arranged over the winter to sell our old Isomat mast to a friend of Howdy Bailey (more on Howdy later) who was building a boat in New Jersey and our first few days were spent getting our old mast ready to be pulled out of the boat for the first time in 40 years.

The boom had to be removed with the Doyle stack pack main sail, and both jibs had to be taken down and bagged. During this time, we would need either a small storage trailer or an SUV to keep the sails, parts, radar, etc. We decided to start with an SUV for a month and see how it went.

On April 5, we moved next to the crane and got ready to remove the Isomat mast.

David Duvall, yard supervisor, rode the crane up to attach a rope that would be used to pull the mast straight up. Donny and Lonny disconnected the roller furlling jib and staysail and the rest of the 11 wires that hold up the mast. Slowly pressure was exerted upwards. Nothing happened. Mike Cobb, the crane operator, was at 5,000 lbs. of lift and still nothing was happening. Time to regroup.

Years ago, as a way to keep the mast from leaking when it rained, we had installed a product called Spartite. Spartite is a two-part polymer that is poured into the space between the mast and the deck, beneath deck level. It hardens and keeps out the water along with keeping the mast in line when you are sailing. David’s experience with Spartite in the past had been that it let go fairly easily when pulling a mast but it didn’t happen that way this time.

If we ever see Kevin Wilson with Stix-n-Rig’n in Kemah TX again, we’ll have to tell him what a good job he did in installing the Spartite! David took out a drill and punched numerous holes in the Spartite, weakening the bond. Then it was time to start with the crane again.

At first nothing happened. David was down below hitting the mast with a rubber mallet to try and loosen it when it LET GO!! The mast jumped up about three feet, La Vita settled back down in the water and the crane bounced back and forth. It was all quite exciting!

Slowly and carefully, the mast was lifted out of the boat in preparation for its new owner.

But the experience of La Vita jumping around and settling back in the water when the mast let go is a perfect example of why reputable yards will not pull a mast unless the boat is in the water. If La Vita had moved around like that hauled out and on jack stands, it could have been disastrous.

As soon as the mast was set up on sawhorses, they moved us around to the lift pit and hauled us for our bottom job. It was at this point that we became aware of a problem Cobb’s Yard was having. Their sewer line connection to the street ran under the yard and years of driving boats on travel lifts across it had taken its toll. The line collapsed and was going to be replaced.

The entire yard, staff and customers alike, were sharing two porta potties that were only emptied occasionally and there were no showers. We had already discussed staying in a hotel for a few days at the start of this project, but this sewer opportunity sealed the decision.

We were glad we had rented a cute little Jeep SUV for the first month and we ended up keeping it for two. It was stuffed full of sails, lines and all kinds of other stuff but it got us back and forth to a hotel quite nicely. And it got us to Walgreens for our first COVID-19 shots the day after we hauled.

While we were off getting our shots, the soda blasting crew set up and went to work. Soda blasting takes off all the old bottom paint so much faster than sanding.

First the boat is wrapped in plastic to protect the hull above the bottom paint. Then small pieces of sodium bicarbonate are blasted at the old paint through a pressure wand. It is very noisy. After the blasting is over, the soda particles are collected, washed and used again. Soda blasting is not as abrasive as sand blasting so it is used often to quickly strip old paint off boat bottoms.

When they were done, La Vita’s bottom was down to the old barrier coat that we had applied in 2009. But soda blasting is not perfect and there were many small divots in the bottom that needed to be faired and filled. So next we (that’s the Royal “We” since Drew did all the work) applied a two-part green filler to the spots and then, after it had hardened, sanded it smooth.

An epoxy barrier coat reduces water absorption by fiberglass boats so it helps keep the hull from becoming waterlogged and developing osmotic blisters. The epoxy barrier coat that we are using is Pettit Protect. It comes in two colors -- white and gray -- that are applied in alternative coats to ensure all the surface is covered. Although Pettit claims a single coat provides significant protection, we went with Cobb’s recommendation for five coats.

We worked out an arrangement with Cobb’s Yard to share the labor, so that we could do some things to save money but they would do the rest. This is one of the really special things about Cobb’s -- they work with their customers. Most yards are not this agreeable to sharing the work. Now it was Cobb’s turn. They taped the bottom and applied the first coat of barrier coat. We applied the next three, one per day. So La Vita went from gray to white to gray to white.

Luckily no sanding was required between coats. When it came time for the last coat (gray), we gave the job back over to Cobb’s. The first coat of bottom paint must be applied within a few hours of the last coat of barrier coat for them to chemically bond and we didn’t think we could time that just right, or make two passes around with paint in one day!

When Cobb’s was done with the first coat of bottom paint, we applied two more coats of Pettit Trinidad SR antifouling bottom paint to keep growth (barnacles, algae, etc.) off. After that was good and dry, Cobb’s people moved the jack stands holding La Vita up and we worked on the 1‘ X 1‘ areas underneath, bringing them up to the same number of coats as the rest of the hull. During this time we also cleaned the propeller and shaft and changed all the zincs.

Zincs are mounted in several places under the water to act as sacrificial anodes. Zinc is a soft metal and will dissolve before the other underwater metals, like the propeller and shaft. The zincs need checked and most likely replaced every year.

During this time in the yard, we also had to prepare for the arrival of our new Selden mast. Although we had requested our new mast be delivered the first week of April, it was now the third week so we were getting a bit anxious. We had moved back aboard La Vita in the yard, as the sewer and water issues were resolved and the bathhouse was open again.

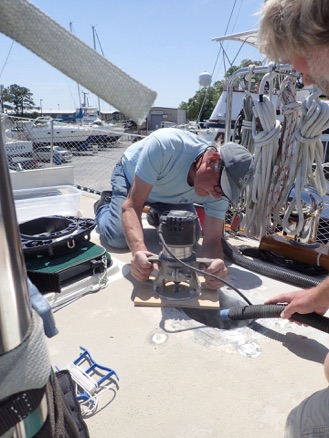

We had removed the radar and radar protection ring from our old mast to use on the new Selden one but the ring had to be modified slightly since the new mast was a different shape. We hired Howdy Bailey Yacht Services to do this and to expand the old hole in the cabin top to accommodate the new Selden mast ring. Howdy Bailey and Larry Foster are legends in this part of the world and we were lucky to get their help. Howdy, now 82, gave up building sailboats a few years ago but still works full-time and has more work than he and Larry can keep up with.

One of the primary drivers for getting a new mast with a furling main was to make it easier to control the sail from the cockpit. As we get older, we want to reduce trips forward in bad weather. The other big project they helped us with to make our lives safer as we get older was to put a dinghy boarding ladder on the stern. When the dinghy is launched from the davits on the stern, one of us has to climb down into the dinghy and help get the outboard engine on its stern. Years ago we were able to do this with an inflatable step but as our knees and backs have aged, this has

become increasingly difficult, especially when putting the dinghy and outboard away when there is a chop in the anchorage. So we designed a three-step ladder that doesn’t go all the way to the water but makes it SO VERY EASY to climb off the stern and get in the dinghy when it is launched. Howdy agreed that it would be much easier to mount this ladder when La Vita was still out of the water and they rearranged their schedule to make this happen. More than one time we heard some early morning noise behind us and looked out to find Howdy up on the scaffolding and already at work, measuring or confirming something. We can only hope we have his energy, sure-footedness and wonderful positive attitude about life when we are 82!

It was now near the end of April and our new Selden mast was finally here! Cobb’s unloaded it from the trailer and set us up in a quiet place along the back fence. We saw our riggers for about an hour as they unpacked the box and put on the spreaders but we had high hopes that the mast would be ready in a week or two when we were back in the water. Turns out we were a bit naive.

We finished up our bottom work and scheduled May 7 with Cobb’s as the day to go back into the water (we had been out one month and two days). During this time, we spent three of those weeks in a hotel, first because of the yard’s sewer problem and later because it was too hot to stay on the boat. We had a rental SUV for the entire time, both for transportation and storage of the two head sails, the radar, radar ring and a ton of other stuff. But now that we were in the water, even without a mast, it felt like a major milestone! Unfortunately we still did not have the attention of the rigger so instead of relaxing, we were forced to start work on commissioning the new mast ourselves. Luckily Cobb’s Marina had room for us to stay for a couple of months until we were ready to put the mast back in the boat and get measured for a new main sail. Stay tuned for our next update, which will detail our DYI mast commissioning and notes on “how to keep calm in difficult times”. Thanks for reading.