Winter and Spring in Hampton VA

Sunday, October 22, 2023

As with all of the places we have stayed for an extended period of time, there was a mixture of good and bad, ups and downs, highs and lows – you get the idea. In Hampton, it was a lot colder than we expected so we did not get the easy access to groceries we had planned (too cold to walk the mile to the grocery store a lot of days) and outside projects were put on hold. But on the positive side, we really liked the staff at Safe Harbor Bluewater. Dave, the harbormaster, Brandon, Jackie and Anita were all really nice and truly wanted us to be happy there. And of course we found some good local restaurants.

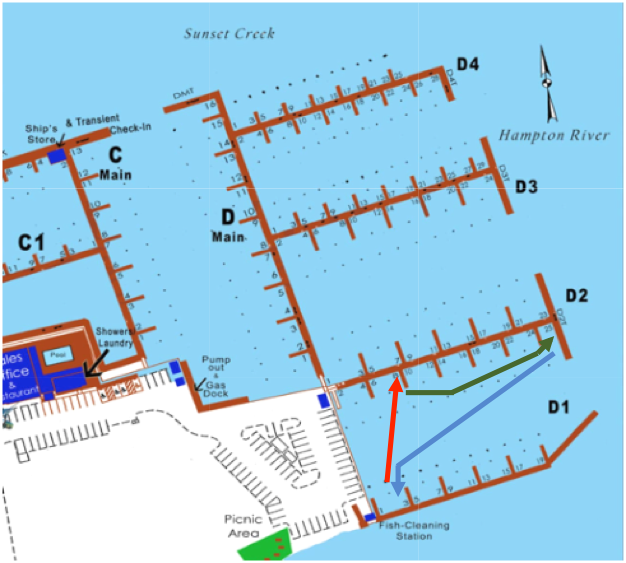

After we returned to Hampton from our visit to Texas over Thanksgiving, the Salty Dawg boat that was in our contracted 50’ slip finally left so we said goodbye to our 55’ slip with the full finger pier and backed out to move one pier over and much closer to the parking lot. Unfortunately we were unable to actually get into our 50’ slip. It wasn’t even low tide, yet we stopped abruptly well short of where we needed to be to use the short finger pier. No worries, Brandon moved us back to pier D2 into another 55’ slip for the same price and it was still much closer to the parking lot for those cold icy mornings.

We were there about two weeks when a strong winter storm blew through. The powerboat that was next to us was poorly tied and worked up quite a bit of momentum in the 50 kt wind gusts, so much so it broke the piling we were both tied to in half.

It made quite a cracking sound and we rushed out to find out what happened. We had to quickly remove out lines from the sinking piling and called the marina office. Brandon and Aaron did their best to secure the piling so it wouldn’t sink or hit us, but the wind was still honking and nothing more could be done until the storm was over. Luckily the piling was down wind for us so unnecessary as long as the wind was out of the north.

We added bumpers between our hull and the piling just in case. We were very concerned that if one

piling broke in this storm, others might and those might be

important to holding us in the right place in the slip. So we got out long lines and climbed on the boat on the other side of us to tie up better. We also checked that boat’s lines to ensure he didn’t fall down on us.

We were able to secure our bow across the stern of the boat next to us without any problem. But we were still heeling over a lot with the wind gusts so we tried something new – we tied our mast to a piling to help keep us upright.

This is not a move we would have considered with our old mast and gooseneck but the new Selden mast is so much heftier than the old Isomat one, we were confident it would not be a problem. Drew worked out a modified trucker’s knot to tighten the line that went around our mid-ship piling. The boat next to us wasn’t using that piling at all so we were guardedly optimistic that it would not break just keeping us from heeling over. And it all worked quite well! The rest of the day was much more comfortable and eventually the storm blew itself out.

But obviously this was not a good long-term tie up. Eventually the wind would come up out of the south again and the piling we needed for that wind direction was broken. Plus, who wants to be in a slip with a broken piling next to them. Bluewater would have the piling replaced at some point, but we needed it now and we really didn’t want to be in the slip when a barge and pile driver came in to remove and replace the piling.

So it was time to move slips again.

A Diagram of our Travels Around the Marina Before we Got Settled

All the 50’ slips on D1 were taken except the one we couldn’t get into due to depth. And there were only two unoccupied 55’ slips, both on D2. One we were in and it had a broken piling and the other was the slip at the end of the pier that we moved out of a month earlier. So back we go to the slip inside the T-head that had a full finger pier but was exposed to south fetch from the bay. We guessed it was just meant to be.

That was pretty much all the excitement for the winter. Once we were back in our “permanent” slip at the end of D2, we worked on a couple of projects and tried to stay warm until April. One really good thing about this slip is that we were close to Kathy and Harry on Water Music again. And their wonderful border collies, Kate and Leo.

So this was where we spent the rest of the winter, with a full finger pier, good neighbors and a great view on calm days. And there were only a couple of icy days where we stayed on the boat until the ice on the dock thawed. Bluewater had a good method for keeping the water flowing during the winter. They turned off the water that ran under the docks but they spread hoses with intermittent connection points down the docks. Then on days that a freeze was expected, it was easy for the marina to turn off the temporary hoses but the rest of the time we could get water when we needed it. To keep the moisture down in the boat, we showered in the marina bathhouse and all-in-all it was a good winter.

We were by ourselves on Christmas so we cooked a Christmas roast. It was a first for us and turned out quite well.

When we were in Cocoa FL at the beginning of COVID, we tried Instacart delivery of groceries but were not happy with the results. There was about a 50% error rate in what we received. Instacart always made the money part work but we didn’t always want what we ended up getting. If we had wanted sliced

Cheddar cheese, we would have ordered that instead of ordering block cheese. If we had wanted Stubbs Sweet BBQ sauce, we would have ordered that instead of Stubbs Original BBQ sauce. You get the idea – nothing major, just annoying.

Hampton VA has a great Amazon delivery hub so here we shifted to Amazon Fresh delivery and it worked great! All the produce was fresh and everything else was exactly what we ordered.

And they would also deliver wine. Having this option made it possible to walk to the grocery store only on nice days and we didn’t have to rent a car nearly as often.

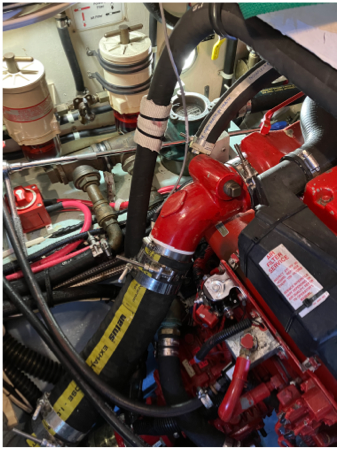

We did focus on a couple of projects that had been on our to-do list for a long time. We had wanted an exhaust riser on our Westerbeke engine exhaust elbow to raise the distance between the water in the muffler and the engine exhaust manifold, thereby increasing the chance that we would not get water in the engine in rough seas. But this project had to be done in two pieces and that took time. Luckily, we had lots of time this winter.

First we found and ordered the correct size V-Band flange from Joey Fanguy in Houma LA. Normally this is used on turbo chargers on little souped up cars. Then we took that to Atlantic Diesel in Hays VA. We had been to Atlantic Diesel before to get Westerbeke parts – it is at the end of the road in the middle of a pasture but they have some of everything. They also have an excellent exhaust fabricator who took the V-band flange and attached it to a custom built riser. The special flange was necessary to attach it to our engine, most of Atlantic Diesel’s flanges were flat and used a gasket. That wouldn’t work with the Westerbeke exhaust elbow.

On the left is the before picture and on the right is the after picture of the new exhaust riser. We got several more inches of height to help prevent water intrusion and were very happy with the result. It just took time to get all the pieces put together.

The other project we wanted to take on this winter/spring was moving the life raft from being stored in a cockpit lazarette to permanently mounted outside on the aft end of the boat.

When we first purchased our Winslow life raft in 2006, we had it packed in a hard valise. This hard valise was not rated for outside storage but it fit perfectly in our lazarette. And our 2006 muscles could pick this 60 lb. package up and bring it out of the lazarette. But as we have aged, picking the life raft up and getting it ready to heave over the lifeline became harder and harder. More and more life rafts are being stored on the rail instead of the deck just for that reason and we saw several examples, both good and bad, on Salty Dawg boats in Hampton before their Rally.

First we booked some fabrication time with Mike Sheehan at S&S Fabricators for May. Mike made our hardtop six years ago and also our auxiliary fuel tank in the bow and does excellent work. We planned for the new life raft holder to attach in part to one of the legs of the hardtop but we were definitely looking for his input on how to best do this.

Next we purchased the new life raft canister designed for outside storage and arranged with the Life Raft and Survival Equipment Co. in Tiverton RI to repack our raft into it. LRSE allows owners to schedule a “teaching” appointment and be there when the raft is opened and inflated. This was set in April so there would be plenty of time for them to ship the repacked raft to S&S Marine in Norfolk.

We drove to Rhode Island for this “teaching” event and that all went well, except for the transportation. Enterprise only had two vehicles available that week – a Miata and a Dodge Ram 3500 king cab truck. No way the life raft would fit in the Miata so the Dodge truck it was. And Apple maps took us through Yonkers NY at rush hour – YIKES! Anyway, we made it and it was very interesting to see how well our 15 year old life raft has aged.

The technician unfolded the raft and carefully inflated it. They slowly inflate rafts so as not to stress the seams, then the gas cylinder goes off to be inspected and filled before repacking. All the flares and food/water rations are replaced and we had them replace the batteries on the handheld VHF that is packed inside. The only casualty was the second EPIRB that was included in the 2020 repack by the Winslow factory in Florida. No precaution was taken to protect it from damage during the shrink wrapping so it was squished and set off. The battery was dead and the unit was damaged. We had to buy another one. Bummer, but if we had actually needed the raft and then found out it wasn’t working, that could have been very bad.

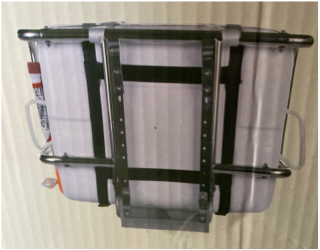

While we were at LRSE, we saw an adjustable life raft holder for the railing. This type of adjustable rail mount is not common in the US and previously we had only seen them on European websites. After a quick call to Mike at S&S Marine, we bought this holder so that Mike could customize it for our raft and not have to start from scratch building one.

The Winslow canister is mostly square, not a rectangle like a lot of life rafts have so this cradle did not quite adjust small enough for the horizontal measurement of our canister, but Mike could fix that. And this model had an extremely well-built back. So many of these rail-mount units have skimpy construction and some only attach to the life raft canister, not form a cradle for it to sit into like we wanted.

This project now was put on hold until May, when we would be at Cobb’s Marina for a bottom job. LRSE would finish repacking our life raft in April and send it to S&S Marine. Mike Sheehan would customize this life raft holder for our canister and mount it on the stern when we were out of the water. It would be much easier to work on scaffolding in the yard than drag the welding rig down the dock and work over the water.

We had one more major project for the “winter”. In 2018 we installed an electric winch on the starboard side of our cabin top for mainsail handling. At that time we thought one electric winch would be enough but with our new furling mainsail, we realized we also need an electric winch on the port side to pull out the sail outhaul at a consistent speed. Consistent speed causes the sail to furl and unfurl in a tighter wrap and avoids jamming the sail when going in or out of the mast. But as with everything it seems, prices had increased so much we were questioning this project. In 2018 the electric winch was $1700. Now the cheapest we could find it was $3100. However, we did remember that in March of each year West Marine does a BOGO (buy one get one free) special on Lewmar winches. West’s price for a single winch was higher ($4200) but if we could get two for that price and sell one for $1500-$2000 then our winch cost would be manageable.

What West Marine did not tell us until we ordered the winches is that there was a three-month back log on building and shipping the winches! Talk about a kink in the plans. First we had the winches shipped to Bluewater in Hampton. Then we moved the shipping to Scott & Tara’s Orlando condo because we had no real idea where we would be in June. Then we ended up back at Bluewater and changed the shipping back to Hampton. What a mess!

It is often said that cruising plans are written in the sand, at low tide. During this first part of 2023, Stephanie was diagnosed with AMD (age-related macular degeneration) in one eye. If there is a good side to this, it is that the type was “wet” as opposed to dry and wet AMD has a treatment (dry does not). The treatment is monthly eye injections for six-eight months, then spreading them out to three-four months between shots. These monthly shots put our Bermuda plans on hold but not our May bottom job at Cobb’s.

This year we did something we had not done in a very long time – we paid Cobb’s to do the bottom job. The thought of the sanding, then the painting and the taping, all the while trying to get the hull waxed and our life raft holder mounted was just too much physical labor for us to take on this year.

But even putting Cobb’s in charge of the bottom job was not without drama – first the Pettit paint they ordered was lost and then found, but damaged (we had visions of large green stains all over a FedEx facility) so the bottom job was delayed. On the positive side, this gave S&S Marine time to finish the life raft holder. Mike showed up with his welding rig to mount the life raft holder and we had the scaffolding ready for him.

The life raft mount was just what we wanted. The back of the mount has two strong connections to the leg of the hard top plus a separate leg to the side of the coming. This mount isn’t going anywhere! The hydrostatic release on the outside of the life raft holder is designed to release the life raft automatically if the boat sinks before we can deploy it. This is one of those safety features you hope you never need but don’t want to be without.

We ended up spending a month at Cobb’s out of the water but the weather was mild and we were able to stay on the boat the whole time. The wonderful interns at Hampton Roads Boater Education pumped out our holding tank twice, the bottom paint was applied, the waxing of the hull was finished and we splashed back in the water on June 1.

It was only a few miles back to Safe Harbor Bluewater in Hampton. We returned to the slip on D2 that had a short finger pier and a replaced aft piling that broke in December. We had to drop the life lines to climb on/off but we managed for the next three months while Stephanie continued her monthly eye shots.

It had now been three months since we ordered our Lewmar electric winches and we had some indications they would arrive soon. Finally we felt that we were going to be able to make progress on this project.

The winches finally arrived on June 22 at the boat yard at Bluewater Yachting Center, delivered on a pallet. Each winch had several boxes, including the winch, the motor, mounting parts, switches and circuit breakers.

Once we started installing the winch, we had to keep moving. The ceiling panels had to be taken down and were underfoot for two weeks while we completed the installation. A hole had to be drilled into the cabin for the winch to attach to the motor and the motor had to be mounted on the roof in just the right place.

The advantage of having installed an electric winch on the starboard side a few years ago, we knew the steps to take and the project went fairly quickly. We didn’t like the push button switch Lewmar sent with the new winches so we bought a different one that matched the starboard side. And we knew we had to buy a winch extension gadget due to the thickness of the Tayana cabin top. Just a note – the extension was $250 in 2018 and $500 in 2023. For a little aluminum tube.

The wiring had to be done and, as more things are added, the spaces to work in become tighter. But Drew got to use his new hydraulic crimper, which made everything a lot easier. Then the ceiling panels had to be cut and reinstalled. On the starboard side there was an instrument box so most of the motor did not show in the main cabin. However, on the port side the entire winch motor was now visible. So Drew built a plywood box around the motor and we attached a fan to point at the nav station. We thought this would just be temporary until we found a carpenter to build a teak box but it looks good so we may just throw some art on it and keep it the way it is.

Now we focused on selling the second winch on eBay. It took a couple of weeks longer than we had hoped so we had boxes underfoot, but

we were able to sell it for $1700, making our net cost, after shipping and rebate certificates, about $2300 for our new Lewmar EVO45 electric winch. Not too bad!

But our stay in Hampton and at the yard in Norfolk was not all work. For our anniversary, we went to the Freemason Abbey restaurant in Norfolk. Formerly a Presbyterian church, the restaurant was on Freemason Street and, contrary to how its name sounds, never belonged to the Freemasons.

It was a beautiful building, with some of the original stained glass windows still in place. We dined upstairs so we had a good view of the interior.

Drew had a seafood pasta dish but Stephanie’s was definitely the better plate - seared scallops on a bed of creamy orzo. Where had creamy orzo been our whole lives?

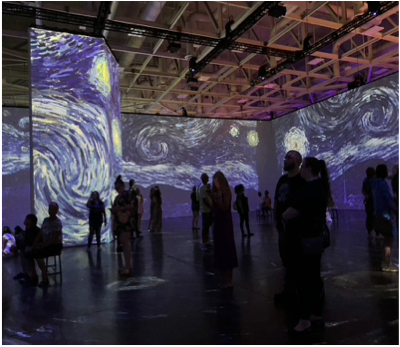

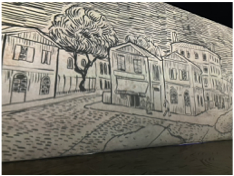

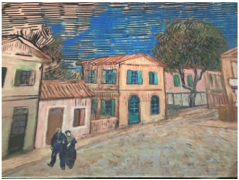

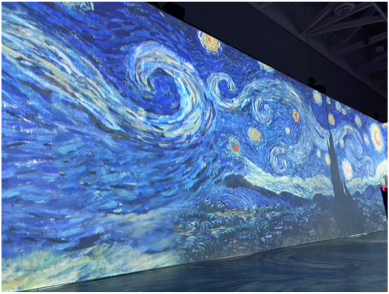

We also went to the Beyond Van Gogh exhibit in Virginia Beach. There are several different versions of digital Van Gogh traveling the world. Some have each of his major paintings in a separate room and you walk between this. Beyond Van Gogh put you in the room and changed the art around you. We really

enjoyed the exhibit and it reminded us of “Vincent”, the production by Leonard Nimoy about Van Gogh from the perspective of Van Gogh’s brother Theo based on Vincent’s many letters to him.

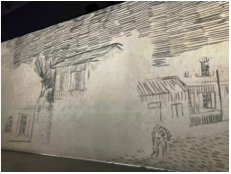

One presentation showed the progression of van Gogh’s painting, from sketch to finishing touches in time lapse. It felt like you were actually watching over van Gogh’s shoulder as he created this French street scene.

But the detail on “The Starry Night” and “Starry Night on the Rhone” as they unfolded around us was absolutely amazing.

We also had some family time with our Texas family in Folly Beach, SC. Stephanie’s father, brother and his kids met us in South Carolina. We explored Charleston and spent time at the beach but forgot to take pictures – we were having too much fun.

But it had become expensive to have so many rental cars in Hampton and the slip rental itself was pricey so we decided to run up Chesapeake Bay to the Anchorage Marina in Baltimore. As we have said before, we love the Anchorage Marina. It is close to everything you need so rental cars are only needed for trips out of town.

We motor sailed overnight from Hampton to Baltimore and had a beautiful full moon to enjoy. Once we were in Baltimore for a few weeks, we planned to drive to Norfolk for Stephanie’s next eye shot and fly to Orlando for other medical appointments and to visit with our Florida family.

We plan on spending 4-6 weeks in Baltimore before heading south again, slowly.

Currently we have reservations at Brunswick Landing Marina in Georgia for three months, starting 11/15. They didn’t have any room until then. We have a couple of things to do on the boat and then plan on spending three months in the Bahamas. Of course this is all written in the sand, but we are going to do our best to get in some real sailing early next year.

Thanks for catching up with us and see you next time .....